The Functions of Internal Components in Solar Road Stud Lights

Jun 12, 2024

Solar road stud lights are innovative devices designed to enhance road safety by providing clear, illuminated guidance to drivers. These devices are composed of several internal components that work together to ensure optimal performance and durability. This article explores the functions of the key internal components of solar road stud lights and how they contribute to the overall functionality of these essential traffic management tools.

Function:

* Solar panels are the primary source of energy for solar road stud lights. They capture sunlight during the day and convert it into electrical energy, which is stored in the internal batteries.

Details:

* Typically made from high-efficiency photovoltaic cells, solar panels are designed to maximize energy absorption even in low-light conditions. Their placement on the top surface of the road studs ensures maximum exposure to sunlight.

2. Rechargeable Batteries

Function:

* The rechargeable batteries store the electrical energy generated by the solar panels. This stored energy powers the LEDs during nighttime or low-light conditions.

Details:

* Commonly used battery types include lithium-ion or nickel-metal hydride batteries, known for their high energy density and long lifespan. Proper battery management is crucial to ensure consistent performance and longevity of the road studs. 3. LEDs (Light Emitting Diodes)

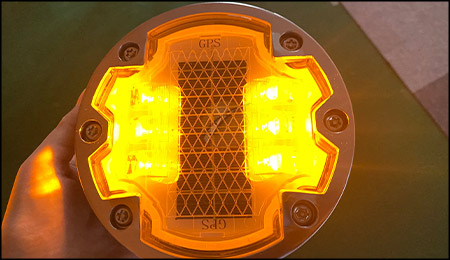

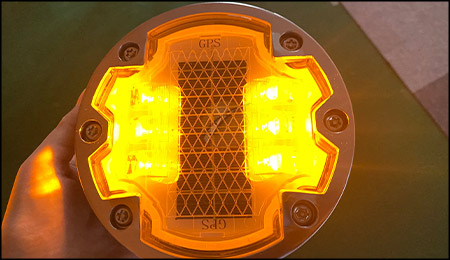

3. LEDs (Light Emitting Diodes)

Function:

* LEDs are the light sources in solar road studs, providing the illumination necessary for road visibility and safety.

Details:

* LEDs are chosen for their energy efficiency, brightness, and long operational life. They are available in various colors, such as white, red, blue, green, and yellow, each serving specific traffic management functions like lane marking, warnings, and guidance.

4. Control Circuit

Function:

* The control circuit regulates the operation of the solar-powered road studs, managing the charging and discharging of the batteries and the activation of the LEDs.

Details:

* This circuit ensures that the LEDs only turn on when needed, typically during low-light conditions. Advanced control circuits may also include features like light sensors and timers to optimize energy use and enhance functionality.

5. Light Sensors

Function:

* Light sensors detect ambient light levels and control the switching on and off of the LEDs accordingly.

Details:

* These sensors ensure that the LEDs are automatically activated at dusk and deactivated at dawn, conserving battery power during daylight hours. They are crucial for the autonomous operation of the road studs.

6. Housing and Protective Cover

Function:

* The housing and protective cover provide structural integrity and protect the internal components from environmental factors.

Details:

* Typically made from durable materials such as aluminum alloy or polycarbonate, the housing is designed to withstand heavy traffic loads and harsh weather conditions. The protective cover, often made from tempered glass or high-impact plastic, ensures that the solar panels and LEDs are shielded from damage while allowing maximum light transmission. 7. Reflectors

7. Reflectors

Function:

* Reflectors enhance the visibility of the led road studs by reflecting vehicle headlights, providing an additional level of safety even when the LEDs are not illuminated.

Details:

* Integrated into the housing, these reflectors are made from highly reflective materials that ensure they remain effective in various lighting conditions. They complement the LED illumination by providing passive visibility.

8. Sealing and Waterproofing

Function:

* Sealing and waterproofing elements protect the internal components from water ingress, dust, and other contaminants.

Details:

* High-quality seals and waterproof designs (typically rated IP67 or higher) ensure that the road studs remain functional in all weather conditions, including heavy rain and flooding. Proper sealing extends the lifespan of the device by preventing internal corrosion and short-circuits. The internal components of solar road stud lights are intricately designed to work together, providing reliable and efficient illumination for road safety. Solar panels capture and convert sunlight, rechargeable batteries store energy, LEDs provide light, control circuits manage operations, light sensors ensure automatic functionality, and robust housing protects the system. Reflectors and waterproofing further enhance the durability and effectiveness of these cat eye road studs. Understanding these components highlights the sophisticated engineering behind solar road stud lights and their crucial role in modern traffic management systems.

The internal components of solar road stud lights are intricately designed to work together, providing reliable and efficient illumination for road safety. Solar panels capture and convert sunlight, rechargeable batteries store energy, LEDs provide light, control circuits manage operations, light sensors ensure automatic functionality, and robust housing protects the system. Reflectors and waterproofing further enhance the durability and effectiveness of these cat eye road studs. Understanding these components highlights the sophisticated engineering behind solar road stud lights and their crucial role in modern traffic management systems.

1. Solar Panels

Function:

* Solar panels are the primary source of energy for solar road stud lights. They capture sunlight during the day and convert it into electrical energy, which is stored in the internal batteries.

Details:

* Typically made from high-efficiency photovoltaic cells, solar panels are designed to maximize energy absorption even in low-light conditions. Their placement on the top surface of the road studs ensures maximum exposure to sunlight.

2. Rechargeable Batteries

Function:

* The rechargeable batteries store the electrical energy generated by the solar panels. This stored energy powers the LEDs during nighttime or low-light conditions.

Details:

* Commonly used battery types include lithium-ion or nickel-metal hydride batteries, known for their high energy density and long lifespan. Proper battery management is crucial to ensure consistent performance and longevity of the road studs.

Function:

* LEDs are the light sources in solar road studs, providing the illumination necessary for road visibility and safety.

Details:

* LEDs are chosen for their energy efficiency, brightness, and long operational life. They are available in various colors, such as white, red, blue, green, and yellow, each serving specific traffic management functions like lane marking, warnings, and guidance.

4. Control Circuit

Function:

* The control circuit regulates the operation of the solar-powered road studs, managing the charging and discharging of the batteries and the activation of the LEDs.

Details:

* This circuit ensures that the LEDs only turn on when needed, typically during low-light conditions. Advanced control circuits may also include features like light sensors and timers to optimize energy use and enhance functionality.

5. Light Sensors

Function:

* Light sensors detect ambient light levels and control the switching on and off of the LEDs accordingly.

Details:

* These sensors ensure that the LEDs are automatically activated at dusk and deactivated at dawn, conserving battery power during daylight hours. They are crucial for the autonomous operation of the road studs.

6. Housing and Protective Cover

Function:

* The housing and protective cover provide structural integrity and protect the internal components from environmental factors.

Details:

* Typically made from durable materials such as aluminum alloy or polycarbonate, the housing is designed to withstand heavy traffic loads and harsh weather conditions. The protective cover, often made from tempered glass or high-impact plastic, ensures that the solar panels and LEDs are shielded from damage while allowing maximum light transmission.

Function:

* Reflectors enhance the visibility of the led road studs by reflecting vehicle headlights, providing an additional level of safety even when the LEDs are not illuminated.

Details:

* Integrated into the housing, these reflectors are made from highly reflective materials that ensure they remain effective in various lighting conditions. They complement the LED illumination by providing passive visibility.

8. Sealing and Waterproofing

Function:

* Sealing and waterproofing elements protect the internal components from water ingress, dust, and other contaminants.

Details:

* High-quality seals and waterproof designs (typically rated IP67 or higher) ensure that the road studs remain functional in all weather conditions, including heavy rain and flooding. Proper sealing extends the lifespan of the device by preventing internal corrosion and short-circuits.